A disruptive and more accessible approach to carbon capture

Carbon capture has been established as a promising solution to remove industrial CO₂ emissions. However, implementation has been slowed down by barriers such as high costs, complexity of the installation and lack of robustness, dependence of access to residual heat, energy consumption and availability, and growing HSE concerns.

Our proprietary technology, Carbon Capture by Nature, significantly reduces these barriers and make capture installations more accessible to targeted industries, such as lime, cement, fertilizers and bio/waste to energy producers. By significantly reducing the cost of capture, eliminating the need for access to residual heat, reducing integration costs and complexity, avoiding HSE concerns, and delivering a robust, autonomous and universal solution to emitters, our Carbon Capture by Nature technology represents a disruptive innovation in the carbon capture market.

Non-toxic and 100 % clean

A water-based process without toxins, amines or other harmful chemicals provides an HSE-friendly operation with no local emissions or chemical handling.

Superior energy efficiency

Low Opex for carbon capture due to a robust low maintenance process with high energy efficiency including incorporated energy recuperation elements.

Robust and scalable

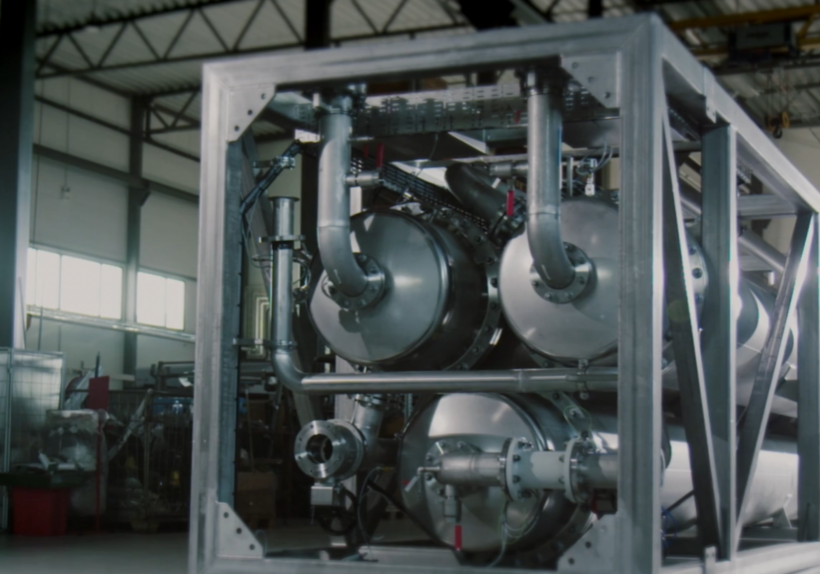

A versatile and modularized technology, robust to chemical composition of the flue gas with no degradation of absorbent.

Low staffing needs

Fully autonomous operation with low staffing needs. Cloud based data storage and accessibility to digital services.

No need for waste heat

A 100 % electrically powered process makes the solution more accessible across industries. No need for residual heat lowers the complexity of integration.

An innovative and clean solution

Our carbon capture method sets a new standard for safety, sustainability, and cost-efficiency. Unlike many competing methods that rely on hazardous chemicals that pose increasing health, safety and environmental concerns, require additional emissions permits, and have limited lifespans, our process eliminates these drawbacks entirely.

We utilize materials that are both safe for human and environmental exposure, are highly affordable, and produce no harmful byproducts. By choosing our process, businesses can ensure compliance with evolving regulations, reduce operational risks, and achieve significant cost savings, all while demonstrating a strong commitment to environmental responsibility.

A cost-effective alternative

Most established carbon capture processes are extremely energy-intensive, relying heavily on heat input and residual heat from the emitter’s operations. These solutions often require large, complex heat exchange systems, leading to high capital costs and challenging integration. Even when residual heat is available, their significant energy consumption remains a major concern. For industries without access to sufficient waste heat energy, adopting these processes becomes unfeasible.

In contrast, we offer a highly energy-efficient, electrically powered carbon capture process that operates independently of residual heat. Energy consumption is further minimized through seamless integration with energy recuperation. Our end-of-pipe design connects directly to the flue gas stack, requiring no additional plant integration, dramatically reducing implementation complexity and costs. Fully autonomous, the system eliminates the need for staffing to a minimum and ensures secure cloud storage for all process data, enabling visualization and other digital services through an intuitive interface. This robust, low-risk solution delivers safe, stable and cost-effective operations with minimal human intervention.

A water-based point source capture technology

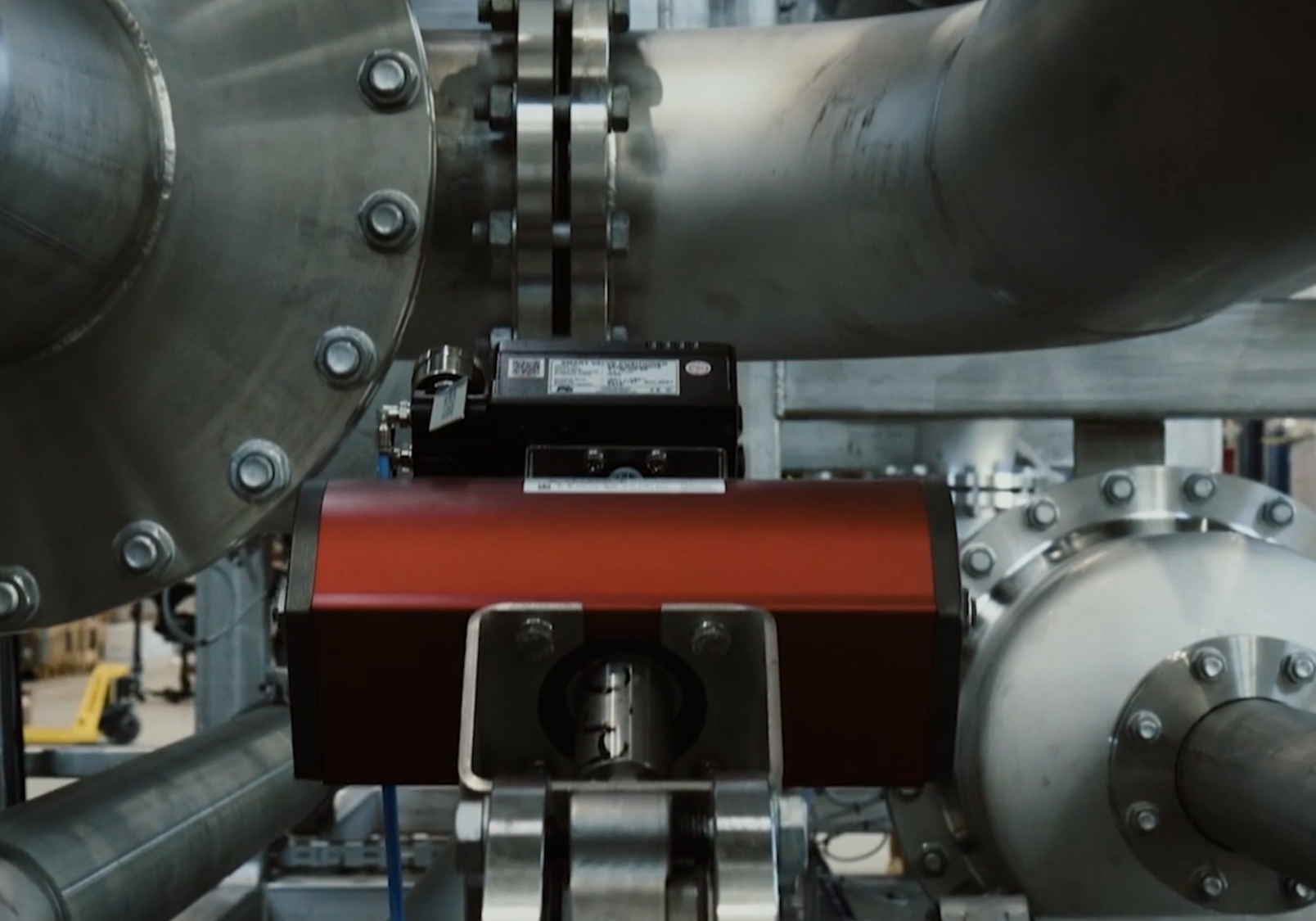

Our water-based innovative technology eliminates the need for harmful chemicals. By further use of “pressure swing” operating method and strategic investment in autonomous operation, a robust, electrically driven and fully automized solution has been achieved, even without need for residual heat.

Highly soluble and acidic components, such as SO₂ and NO₂, are scrubbed out prior to the gas mixture being pressurized and put into counter-current contact with the absorbent.

The CO₂-rich absorbent is then introduced to the desorption stage in order to extract the CO₂. The resulting lean liquid is then recirculated to the absorption stage, making this a closed-loop process that conserves the absorbent.

Solutions scaled to your needs

We offer a range of services and products. Through our collaborative approach and accessible services, we lower the threshold and help you to quickly identify and develop the optimal carbon capture solution for your needs. Our solutions are designed to ensure the best performance throughout the CO₂ capture process, prioritizing operational safety, efficiency, and cost-effectiveness.

Let's collaborate to decarbonize your operations

Experience a collaborative and agile customer journey together with us. Team Ocean GeoLoop consists of passionate staff, setting high expectations for our deliveries to our customers in all phases, from early phase activities to operations. Below is a general outline of our path to full operations, though we adjust it based on your specific project. Book a meeting today, and we’ll create a customized plan for your success.

1

Pre-qualification

Perform gas analyses or run carbon capture tests of your flue gas composition at our carbon capture test facility in Trondheim to verify that our solutions are compatible with your needs.

2

Feasibility study

Assesses the practicality and viability of the project by analyzing design requirements, concept development, preliminary design, technical, economical and operational factors.

3

Test phase

Further testing at our R&D test facility, or using our mobile test unit.

4

EPCI

Depending on customer processes, engineering, procurement, construction and installation phases are executed to deliver a capture facility.

5

Operations

Our autonomous solution will now capture your CO₂.